Safety & Quality Standards

Our cGMP Certified Breast Milk Freeze Drying Process

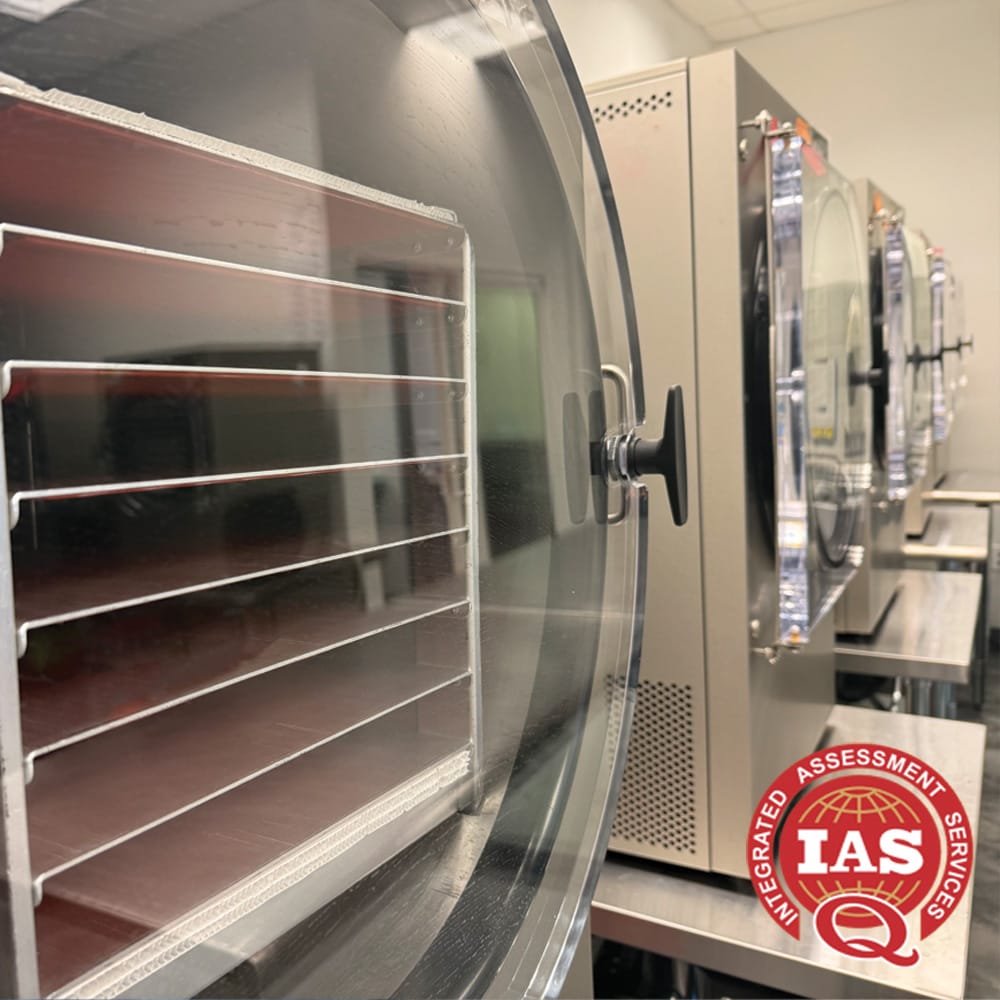

The Assurance of cGMP Certification

Third-party cGMP certification is a cornerstone of our commitment to safety and quality. This rigorous certification process ensures that our freeze-drying methods meet the highest industry standards, providing peace of mind to parents who trust us with their breast milk.

Why cGMP Matters

cGMP, or current Good Manufacturing Practice, is a system that ensures products are consistently produced and controlled according to quality standards. By adhering to these guidelines, we guarantee that our processes are safe, effective, and reliable.

Track and Trace

Each BoobieJuice order undergoes meticulous tracking and tracing throughout the entire process. Upon receipt, each order is documented, photographed, and uniquely tagged. We employ identifier tagging and logging to ensure precise tracking of your bags, including bag dates, times, and any unique notes, such as dietary changes or pump times. This comprehensive tracking system guarantees that all your specific requirements are seamlessly transferred to their new BoobieJuice pouches.

Nutrient Preservation and Quality

Low Temperature Calibrated Sublimation is a key process in our freeze-drying technique, crucial for preserving the nutrients in breast milk. This method involves removing moisture without exposing the milk to high temperatures, which can degrade sensitive nutrients. By transitioning directly from a solid to a gaseous state, sublimation ensures that vitamins, minerals, and other vital components remain intact. This process not only maintains the nutritional profile of the milk but also enhances its shelf life, providing a convenient and reliable option for parents.

At BoobieJuice, we never bulk process multiple clients’ breast milk together in one large freeze dryer. Every mother’s milk is handled as an individual batch, processed separately and exclusively in its own dedicated sublimation pouch and in its own machine. This single-batch method eliminates any possibility of cross-contact during the freeze-drying process, ensuring maximum purity and safety for your personalized breast milk powder.

Our unique temperature-controlled sublimation process is at the heart of BoobieJuice’s freeze-drying method. By precisely managing the drying environment and product temperatures throughout, we protect the nutritional integrity of your breast milk—preserving essential proteins, fats, antibodies, probiotics, and other bioactive components. The result is a high-quality, fully dry, shelf-stable breast milk powder that safely meets your baby’s dietary needs using your very own milk.

Advanced Testing Protocols

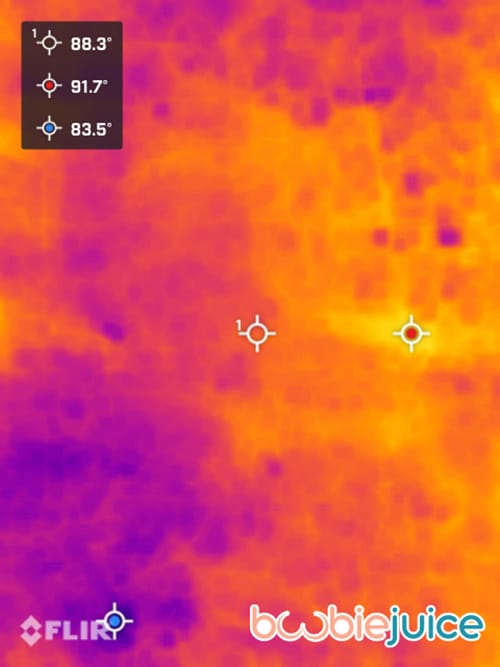

Ensuring Safety and Quality

At BoobieJuice, we prioritize the safety and quality of our freeze-dried breast milk through rigorous laboratory testing. Our protocols include comprehensive on site rapid environmental microbial testing to detect any potential contaminants, ensuring that every batch meets the highest safety standards along with 3rd party environmental testing. The use of FLIR Thermal imaging to ensure product temperatures stay within human body temperature ranges and minimizing nutritional degradation. Water activity testing confirms final dryness well below bacterial growth limits and even below lipase enzyme functions limits. All equipment is remotely monitored and temperature logged. We employ Middle-infrared Spectroscopy and offer ICPMS & HPLC Testing and validation, guaranteeing that the essential nutrients remain intact throughout the process. Our commitment to quality is reflected in our adherence to stringent testing procedures, providing peace of mind to our customers.

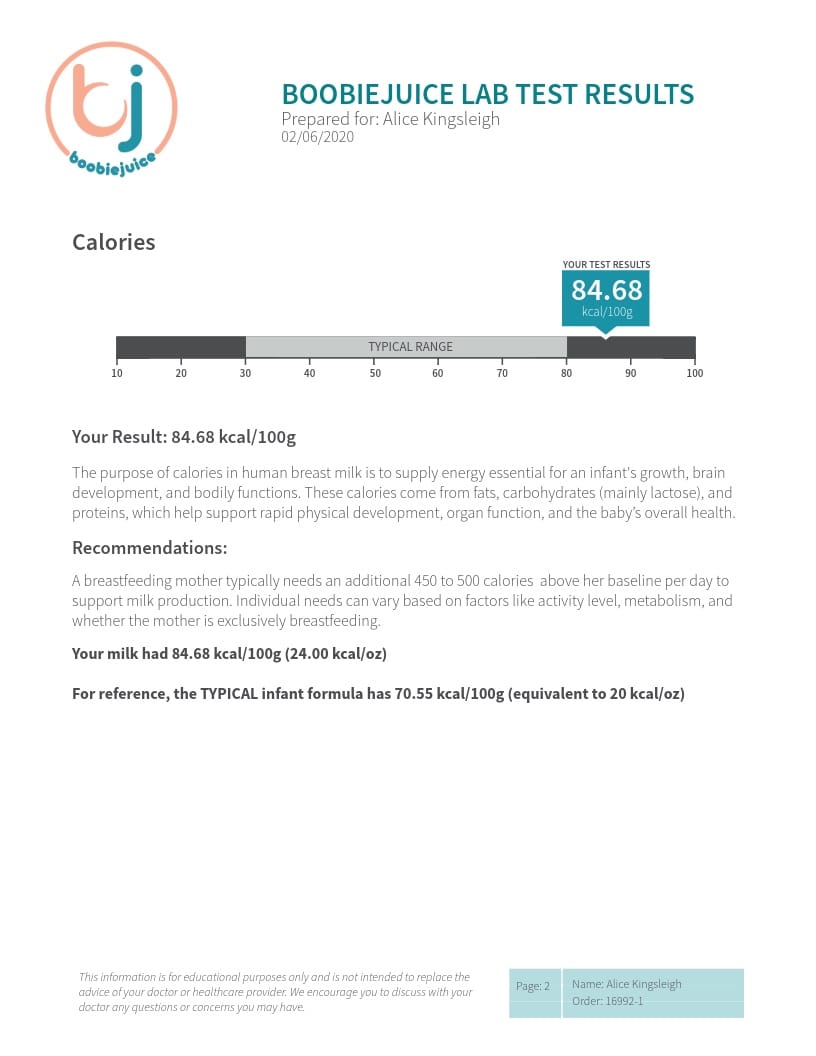

Nutritional Analysis and Testing

Our entire process, from inbound shipping to freeze-drying, is meticulously designed to maintain the integrity of your breast milk and maximize nutritonal results while creating a dry, shelf stable solution. We employ the latest technology to precisely assess the quality and nutritional value of our control processes to ensure that your milk retains it natural composition and rehydrates back to its original density. Macro nutritional testing validates the content, ensuring that your freeze-dried milk retains its nutritional density when rehydrated. While water activity ensure we are below bacteria growth levels and lipase function levels.

We also offer nutritional testing as a stand alone service!

High-Barrier Packaging

Made in the USA Pouches

Our high moisture barrier USA made packaging is designed to protect the freeze-dried breast milk from environmental factors that could compromise its quality. Our materials are BPA free and Phthalate additive free. This packaging provides an effective barrier against moisture, oxygen, and light, all of which can degrade the product. By using materials that are both durable and safe, we ensure that the milk remains fresh and nutritious until it is ready to use. This level of protection is essential for maintaining the product’s integrity and ensuring the quality and safety for long term storage.

Our high-barrier packaging offers benefits beyond mere protection. It plays a pivotal role in preserving the nutritional and safety standards of our freeze-dried breast milk. Each BoobieJuice pouch undergoes chamber vacuum sealing, which removes excess oxygen to maintain the taste and aroma of the breast milk powder and helps extend its shelf life. By further reducing oxygen exposure and minimizing elemental exposure, the packaging helps maintain the milk’s quality, ensuring it remains a dependable source of nutrition for infants.

Sterile Handling in ISO 5 HEPA Chambers

Maintaining Product Integrity

BoobieJuice gently freeze-dries your breast milk through a controlled sublimation process until water activity testing confirms the powder has reached extremely low levels—well below the threshold where bacteria can grow or thrive. This precise drying also effectively halts lipase enzyme activity, preventing the breakdown of fats that can otherwise alter the milk’s nutritional profile, taste, and aroma (such as the soapy or metallic flavors common in high-lipase milk during storage).

All final packaging occurs in our ISO 5 HEPA-filtered chambers, which provide a highly sterile, controlled environment. These advanced cleanrooms use sophisticated HEPA filtration systems to remove airborne particles and contaminants, ensuring your milk powder remains pure and free from cross-contamination throughout the process.

Finally, we remove oxygen completely by vacuum-sealing each pouch in a commercial-grade chamber vacuum, creating an airtight barrier that enhances shelf stability, preserves nutritional integrity, and protects against degradation for up to 3 years when unopened.

Temperature controlled & Remote Monitored

BoobieJuice Cold Storage

BoobieJuice stores all incoming breast milk in temperature-calibrated, remotely monitored freezers to maintain optimal quality and safety. Multiple backup generators ensure uninterrupted power in case of outages, and our Arizona location experiences minimal natural disasters, adding extra reliability and peace of mind for mothers.

High Performance BoobieJuice Frozen Shippers

Overnight Frozen Transit

BoobieJuice uses advanced pharmaceutical-grade insulated panel coolers to ensure reliable frozen hold times during transit. These high-performance panels provide 10 times the thermal rejection of standard 1-inch urethane shippers—without needing additional ice packs or dry ice.

Our latest custom insulated coolers feature the highest-grade insulation available in a compact design, delivering longer frozen hold times while keeping shipping sizes smaller and more efficient.

Every inbound order is carefully inspected upon arrival, ID tagged, and documented thermal temperature testing to confirm it stayed frozen throughout transit. We send you clear photos of the arrival condition and weight so you have complete peace of mind that your breast milk arrived safely and ready for processing.